What is FDM 3D printing?

Fused Deposition Modeling (FDM) is one of the largest methods used in 3D printing worldwide. FDM 3D printing is gaining a lot of popularity nowadays because of its credibility generated through fdm 3d printing. It is a type of technology which is also referred to as additive manufacturing process belonging to the family of material extrusion. In simple words, it is a 3D printing process which makes use of continuous filament of a thermoplastic material. The object in FDM 3D printing is constructed by selectively depositing molten material layer by layer over a pre-determined path.

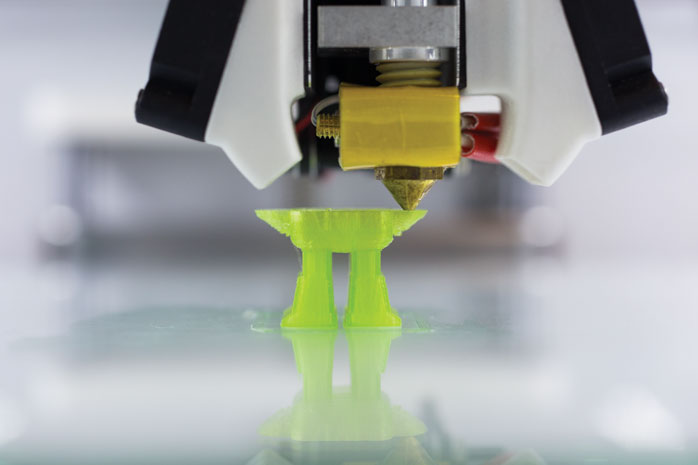

How does FDM 3D printing work?

The FDM 3D printer melts the material into a liquid state at very high temperature. It works both horizontally as well as vertically where the molten polymer is extruded through a nozzle which moves over a build platform. The melted material is then solidified to form a three-dimensional space to form solid object in the end. The initial model is present in a 3D CAD (computer-aided design) which is divided into numerous slices and outputs a G-code file for the printer from a digital model using slicing software. Each slice in the file is converted to a machine code to deposit the first layer of material onto the build platform.

What are the benefits of FDM 3D printing?

- Using an FDM 3D printer is quite easy for an operator. An operator needs a CAD file to convert the digital model easily and quickly. The operator can easily convert the CAD file by uploading it on the device and by making use of a few buttons the entire FDM printing can be handled smoothly generating effective results.

- FDM 3D printer is cost-effective for manufacturers and company owners to build their model all by themselves. The speed of the printer also adds on as a great benefit for the operator or the business. The capability of the FDM 3D printer to print the model is between 2-24 hours. No other printer in the market can generate quick and smooth results as FDM 3D printers.

- The FDM 3D printing allows printing of complex model which is not the case with traditional printers. These printers have their uniqueness of comprehending the digital model and generating the accurate 3D model without any complication inflicted on the operator of the printer. It makes the manufacturing process easy for designers, operators, or business model owners.

- The operator doesn’t need to print every model in bulk like the traditional printing method used for models. The operators can save the digital model and print the required number of models according to the needs and requirements. It not only saves time but also money and raw materials. All the designs can be saved in a virtual library which can be accessed by the operator or designer at any time and from anywhere.

- FDM 3D printing reduces the number of wastage. The 3D printing only consumes material which is required for printing the part or model.